When it comes to fiber laser work, understanding the difference between deep engraving and surface marking is essential for both aesthetics and durability. Whether you’re customizing gear or meeting compliance standards, the depth of your laser matters more than you might think.

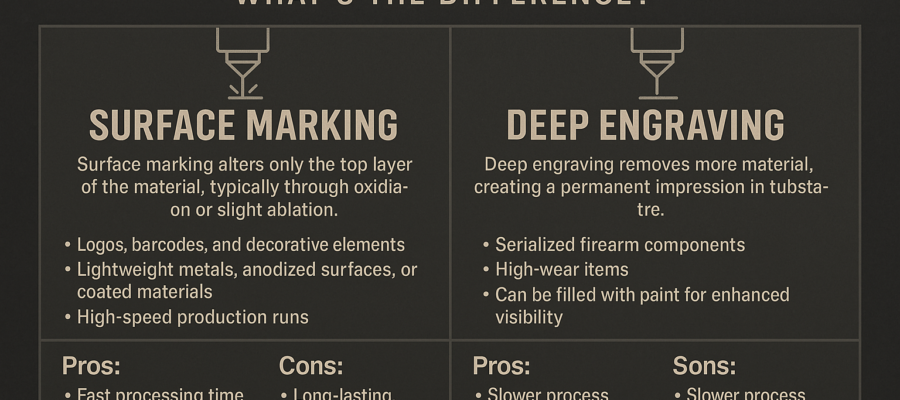

✏️ Surface Marking:

Surface marking alters only the top layer of the material, typically through oxidation or slight ablation. It’s fast, clean, and ideal for:

- Logos, barcodes, and decorative elements

- Lightweight metals, anodized surfaces, or coated materials

- High-speed production runs

Pros:

✅ Fast processing time

✅ Minimal material removal

✅ High contrast on anodized or coated surfaces

Cons:

❌ Not durable on raw metal

❌ Doesn’t meet ATF depth requirements

🛠 Deep Engraving:

Deep engraving removes more material, creating a permanent impression in the substrate. It’s required for serialized firearm components and ideal for high-wear items.

Pros:

✅ Long-lasting, resistant to abrasion

✅ Legally compliant for serialized engravings

✅ Can be filled with paint for enhanced visibility

Cons:

❌ Slower process

❌ More heat = more chance of material discoloration or warping (if settings aren’t dialed in)

⚙️ Which Should You Use?

| Use Case | Recommended Method |

|---|---|

| ATF Compliant Serial Markings | Deep Engraving |

| Logos on Coated Surfaces | Surface Marking |

| Industrial Tool ID Tags | Deep Engraving |

| Aluminum AR Upper Logos | Surface Marking |

🎯 Final Thoughts

Your laser settings should match your goals. Surface marking might look clean, but for compliance or long-term durability, deep engraving is the way to go.

Up next:

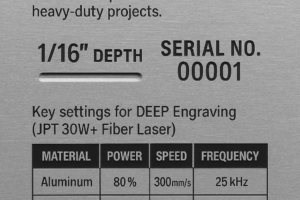

🔜 “Dialing in the Perfect Laser Settings: Power, Speed, and Frequency Explained”

Leave a Reply

Your email is safe with us.