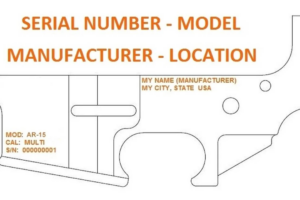

When it comes to tactical applications, not all fiber lasers are created equal. Whether you’re engraving AR-15 lowers, suppressors, knives, or serialized parts for ATF compliance, your gear matters just as much as your precision.

⚙️ Key Features to Look For:

1. Power Output (Wattage)

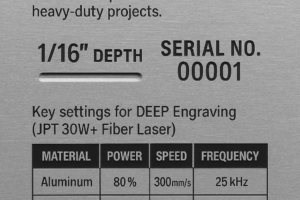

For tactical-grade engraving, 20W to 50W is the sweet spot.

- 20W: Great for small jobs and aluminum/steel engraving.

- 30W+: Faster, deeper marks—ideal for serialized firearm components.

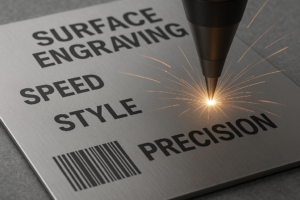

2. Marking Speed & Depth

You’ll want a laser that can hit 0.003″ depth to meet ATF standards. Adjustable pulse duration and frequency give you the control to engrave cleanly without excessive burning.

3. Lens & Field Size

A 110x110mm lens works well for small parts, but if you’re doing AR receivers or NFA items, consider a 175x175mm or larger. Swappable lenses = more versatility.

4. Air Assist & Fume Extraction

Optional but highly recommended. Not only does it keep your lens clean—it keeps your lungs happy.

5. Software Support

Make sure it’s compatible with EZCAD2 or LightBurn (Galvo). You’ll want easy control over vector files, serial numbers, and even barcodes.

💡 Pro Tip:

If you’re engraving serialized firearm components, make sure your laser can hit 1/16” tall characters at the .003″ minimum depth required by the ATF.

🛠 Recommended Brands:

- OMTech Fiber Series

- Max Photonics / JPT LP Series

- Cloudray / HM Tech / SFX

Stay tuned for upcoming posts like: ➡️ “ATF-Compliant Engraving: What You Need to Know”

➡️ “Customizing Tactical Gear with Deep Engraves”

Let the sparks fly, and remember—precision isn’t optional. It’s tactical. ⚡

Leave a Reply

Your email is safe with us.